Activities of the Laboratory include: Static and dynamical material testing, life-cycle evaluations, strain gage measurements, structural analysis, ultrasonic thickness measurements, coating thickness measurements and finite element modelling.

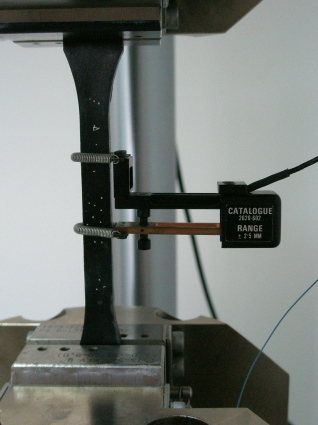

INSTRON 8801 - Servo hydraulic Dynamic Testing Machine

Maximum Load Capacity: ±50 kN

Maximum Daylight: 1100 mm

Tests: Static, Low Cycle Fatigue, High Cycle Fatigure, Fracture propagation

Test specimens: Tension/compression (cyrcular 6-12 mm diameter, flat 0-15.75 mm), 3 point bending, K1C testing on pre-cracked brittle specimens

3.8MB movie: Dinamical testing performed on the INSTRON 8801

INSTRON 9450 - instrumented drop tower system

Maximum speed: 24 m/s

Maximum impact energy: 1800 J

Maximum impact force: 222 kN

Tests:

Charpy test for polymers and metals according to ISO 179, ASTM D6110 and ASTM E23,

Testing of composite polymers according ASTM D7136/D7136M, PR-EN 6038, Airbus AITM 1.0010

15 m/s

Charpy specimen

Compression test of cellular sampleStrain gage measurements

Equpment includes: HBM MGCplus - Modular computer-controllable amplifier system, Force Transducer (HBM Type U5: load capacity 500 kN), Portable computer. Masurements can be performed on various locations (e.g. Measurements in the bedplate (oil-pan) of the 13530 kW diesel engine during the navigation).

Ultrasonic thickness gauge

A small lightweight ultrasonic thickness gauge that enables standard and "through-coatings (paint or rust)" measurements of materials in range of 1.2 - 200 mm.

Coating thickness measurement and cross-cut test

A coating thickness gauge for non-destructive measurement of electroplating, nickel coatings, phosphating, paint, plastic, enamel etc. on steel.

Evaluation of resistance of paint coatings to separation from substrates according to EN ISO 2409.

Vickers hardness and strength testing

AlphaDUR mini is mobile system for evaluation of harndenss and material strength based on the UCI HV10 method.

Leeb hardness testing

DynaRock II is mobile system for evaluation of hardness and material strength based on the Leeb method.

3D scanning

3D high precision laser scanning enables acquiring 3D geometries used for the geometry evaluation, CAD models, FEM models and rapid prototyping.

2.6 MB movie: Scanning.Thermography in nondestructive testing and stress analysis

The infrared camera is used in nondestrucive testing for detecting damage or crack propagation, as well as the stress evaluation of dynamicaly loaded structure. Figure depicts the stress distribution of the plate with the hole.

Aluminium-perlite

Some of examples are illustrated on the page IR expertise examples.

1.8 MB movie: The stress ditribution of the loaded specimen. Applied loadin is sinusoidal loading from 0 to 20 kN with the frequency of 10 Hz.USM Go - Ultrasound testing equipement

NDT ultrasound evaluation of materials including detectoin of fractures, damages, material inclusions and evaluation of weldments.

Penetrant testing

NDT detecion of fractures and anomailes in material.

Tiede TWM 230 A - Hand Yoke

NDT magnetic particles evaluation of materials including detectoin of fractures and evaluation of weldments.